Bodyshop professionals can now maximise their efficiency in vehicle collision repair while keeping costs down by choosing the appropriate high-quality adhesives offered by leading automotive repair solutions brand TEROSON.

Bodyshop professionals can now maximise their efficiency in vehicle collision repair while keeping costs down by choosing the appropriate high-quality adhesives offered by leading automotive repair solutions brand TEROSON.

TEROSON adhesives address the rapidly evolving vehicle maintenance and repair landscape. Leveraging decades of expertise, TEROSON has released a new collision repair pocket guide to help customers better understand its capabilities.

From a small restoration such as a broken bumper, or a more major repair such as structural damage to a vehicle which requires cutting out the old part and replacing it with new ones, a simple and versatile adhesive can fix the issue. Not only do TEROSON adhesives increase productivity, the best-in-class bonds maintain original equipment manufacturer (OEM) finishes to ensure bodyshops keep their outstanding reputations.

The pocket guide summarises the three key areas where TEROSON makes a difference:

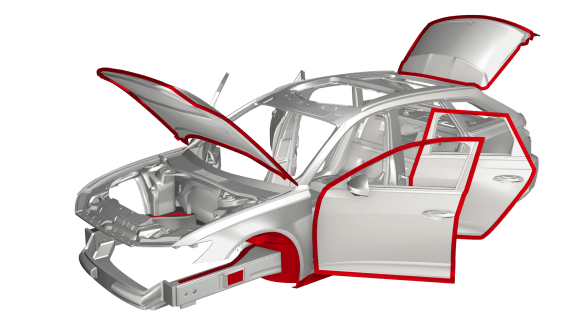

REBUILD: Common tasks that involve rebuilding OEM seams, metal or plastic parts. The adhesive range for rebuilding is broad and mainly chosen based on the substrate(s) that need to be rebuilt. Common technologies are MS, EP and PU. Remember: Rebuilding is often a time- and resource-saving alternative to replacing parts.

REPLACE: Structural damage requires cutting out old parts and replacing them with new ones. Due to the size of the replaced parts, and the need to retain the structural integrity of the car, high-strength, structural bonding power is needed. This is the premium class within collision repair and requires comprehensive knowledge and practice to re-establish original structural integrity.

REPAIR: The things that can be fixed relatively easily, e.g. bumper repair, broken bumper clips, or components of similar complexity. These can be solved quickly with a selection of TEROSON solutions for smart repair.

The solvent-free adhesives provide high-strength, impact resistant solutions that are crash safety tested at extreme temperatures with easy preparation and application, ensuring body shop professionals can take full advantage and further save time.

Key Account Manager at TEROSON Julian Pateman said: “Bodyshops face significant challenges maximising efficiency and keeping costs down. Finding a solution that does both is few and far between, but at TEROSON we have multiple solutions for bodyshop professionals to increase productivity across the board while not feeling the squeeze on their margins.”

TEROSON actively collaborates with customers, suppliers and partners to find the best solution for each customer. By sharing knowledge, TERSON hope to empower all clients in navigating the challenge of making the right choice with adhesives first time, every time.